When it comes to the sensitive cancer drug compounding procedure, healthcare providers urgently need to improve efficiency and safety for all people involved

Until now, chemotherapies protocols compounding procedure is been done manualy, by hospital’s expert staff. This procedure is particularly challenging, and carries important risk, such as

dosing inaccuracies, as the pocess is manual

medication errors, as the final containers or drugs could be incidentaly exchanged

clinical staff risk due to high toxicity

unused drug waste

Innovative technology for compounding patients’ chemotherapy drugs

What is ChemoMaker+

Thanks to its automation, it solves the most of critical issues related to the manual preparation process usually adopted in hospitals.

ChemoMaker+ is an innovative technology for the automated compounding process of patient-specific chemotherapy drugs that offers mutliple benefits.

ChemoMaker+ offers an automated compounding procedure, leading to crucial benefits, such as

- increasing patient safety

- lowering operators’ risk of contamination

- reducing operating costs optimizing the use of drugs

- increasing accuracy

- time-efficient, as it can prepare up to 12 patients’ therapy dose at the same time

Easy and simple installation

ChemoMaker+ is a compact system, that can be easily placed in an existing Class II laminar flow hood. It does not require dedicated spaces or installation works.

How it works

Sterile environment

The system is based on a robotic unit, able to fully automatize the dosing process (i.e.: the transfer of drugs from vials to infusion bags). Patient doses, ready to be administered, are prepared in a sterile environment, and the compounding robot, is placed under a sterile laminar flow hood. A closed system (patent pending) prevents the contamination.

Accurate medicine doses

The proper formulation is guaranteed by a real-time gravimetric control system (patent pending) able to ensure dosage accuracies up to 1%, more than one order of magnitude higher than the precision allowed by the European Pharmacopoeia in manual preparations.

Traceability

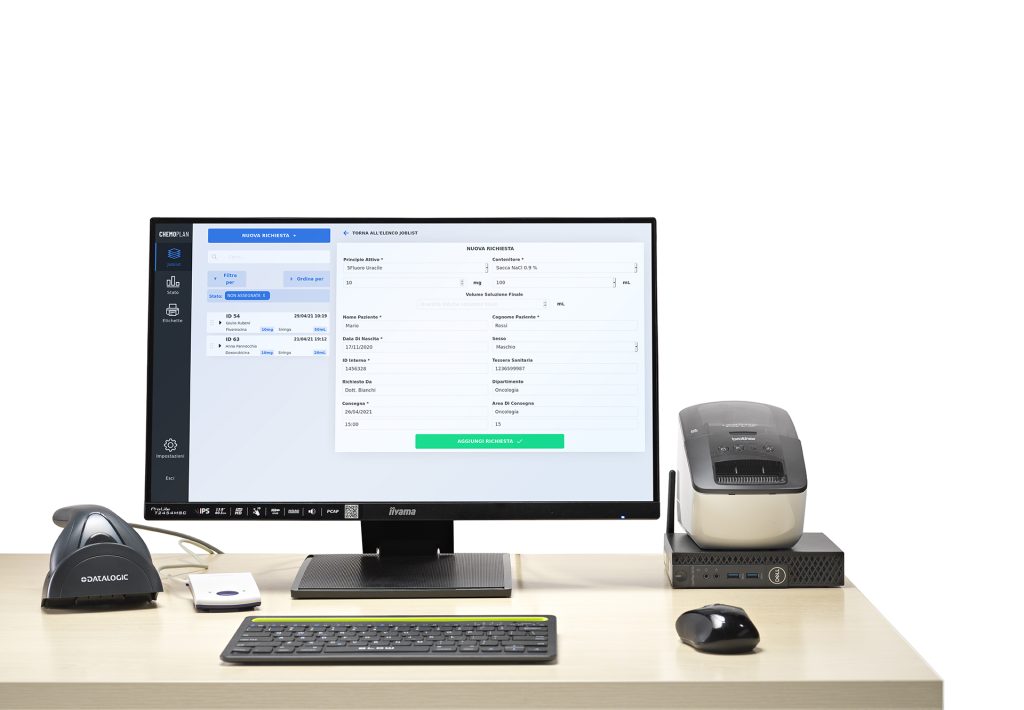

ChemoMaker+ is wireless connected to a computer, which allows the operators of the hospital pharmacy to organize the preparation activity according to the prescriptions received from the oncology departments. All materials are identified by barcodes and RFID tags for maximum safety. Multiple automatic checks assure high accuracy and safety of the final product.

Safety

The drug is dosed directly into the final containers intended for administration (bags, syringes, elastomeric pumps), in order to avoid any subsequent manipulation, preventing contamination for healthcare professionals and patients.

The process

Drugs and final containers are selected according to prescriptions

Drugs are identified by a double-check system: barcode and RFID

Infusion bags are associated to each patient-specific therapy

Drug vials and infusion bags are loaded on the compounder

ChemoMaker+ automatically compounds all medications

Identification labels containing all preparation data and barcode are automatically printed for each dose.